Springfield, MA: Residential Concrete Slab Reinforcement Guide

Concrete Slab Springfield

Springfield homeowners must carefully consider reinforcement options when planning residential concrete slab projects to ensure long-term durability in Massachusetts’ challenging climate. Proper concrete slab reinforcement prevents cracking, improves structural integrity, and extends service life significantly beyond unreinforced installations. New England’s freeze-thaw cycles demand strategic reinforcement selection based on load requirements, environmental exposure, and budget considerations. Professional contractors understand local soil conditions and temperature extremes affecting reinforcement performance throughout Springfield’s diverse neighborhoods. Modern reinforcement options include traditional steel rebar, welded wire mesh, and innovative synthetic fiber systems, each offering distinct advantages. Understanding these choices helps homeowners make informed decisions, protecting their concrete investments while meeting specific project requirements and local building standards.

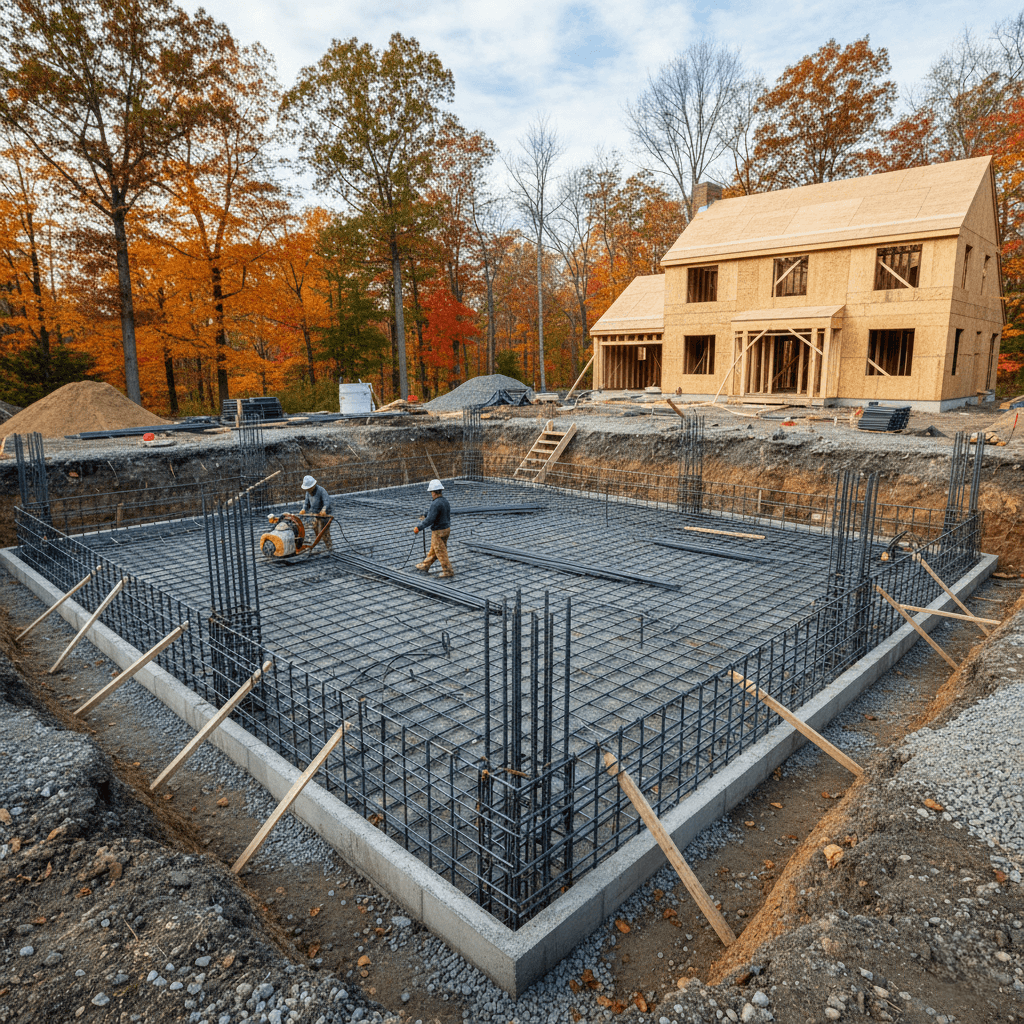

Steel Rebar Reinforcement Systems

Steel rebar provides superior tensile strength, making it ideal for residential concrete slab applications requiring maximum structural capacity. Standard residential installations typically use #3 or #4 rebar spaced 18-24 inches on center in both directions. Deformed rebar features surface ridges, ensuring excellent concrete bonding and load transfer characteristics.

Carbon steel rebar remains most cost-effective for typical Springfield residential projects while offering reliable performance. Epoxy-coated rebar provides enhanced corrosion resistance, which is important in Massachusetts’ humid climate and freeze-thaw conditions. Properties near Springfield College often specify upgraded rebar systems for enhanced durability.

Rebar Placement and Installation

Proper rebar placement requires positioning steel at mid-depth or slightly below center for optimal performance. Rebar chairs and supports maintain correct elevation during concrete placement, preventing displacement. Professional installation ensures adequate concrete cover, preventing corrosion and surface staining issues.

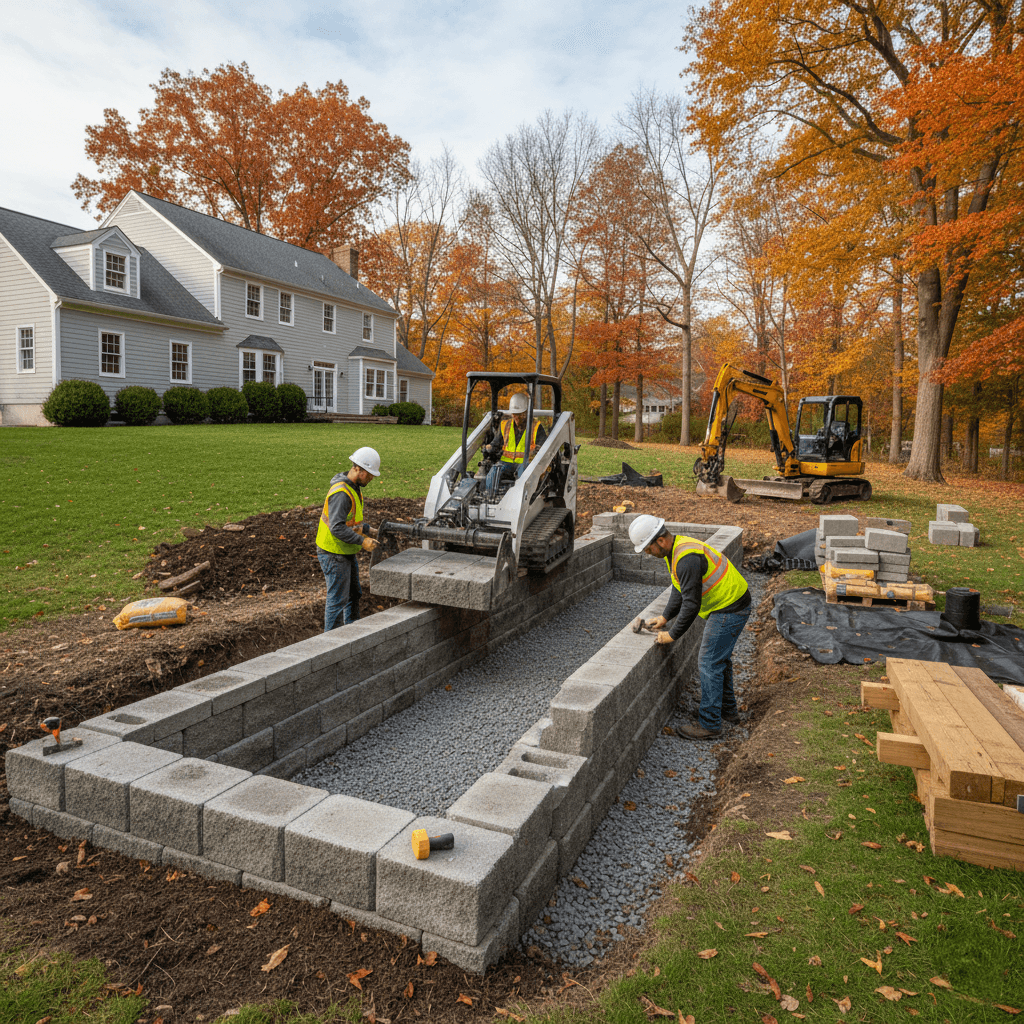

Welded Wire Mesh Options

Welded wire mesh offers cost-effective reinforcement for standard residential concrete slab installations throughout Springfield neighborhoods. Common mesh specifications include 6×6-W2.9xW2.9, providing adequate reinforcement for typical loads. Wire mesh installation requires less labor than individual rebar placement, reducing overall project costs.

Galvanized wire mesh provides corrosion resistance suitable for Massachusetts climate conditions. Stainless steel mesh offers premium durability for challenging environments such as the Memorial Bridge area. Proper mesh support prevents settlement during concrete placement, ensuring uniform reinforcement distribution.

Installation Considerations

Wire mesh sheets require careful handling, preventing distortion that affects reinforcement effectiveness. Overlap requirements ensure continuity across mesh joints, maintaining structural integrity. Properties around Forest Park benefit from mesh reinforcement, reducing crack propagation in expansive soils.

Synthetic Fiber Reinforcement

Modern synthetic fiber concrete reinforcement offers innovative solutions for residential concrete slab projects requiring crack control and durability enhancement. Polypropylene fibers dispersed throughout concrete provide three-dimensional reinforcement, reducing plastic shrinkage cracking. Macro synthetic fibers can replace traditional wire mesh in many applications.

Fiber reinforcement eliminates placement challenges associated with steel reinforcement while providing uniform distribution throughout slabs. Different fiber types address specific performance requirements from basic crack control to structural enhancement. Springfield Technical Community College area projects often utilize fiber systems for improved durability.

Fiber Types and Applications

Microfibers control plastic shrinkage during concrete curing, while macrofibers provide post-crack load transfer capacity. Blended fiber systems combine multiple fiber types, addressing various performance requirements simultaneously. Dosage rates typically range from 3-8 pounds per cubic yard, depending on application requirements.

Climate-Specific Considerations

Springfield’s freeze-thaw cycles create unique challenges requiring appropriate reinforcement selection and installation practices. Air-entrained concrete combined with proper reinforcement systems provides optimal freeze-thaw resistance. Massachusetts building codes influence reinforcement requirements for different applications and exposures.

Moisture management becomes critical in preventing corrosion of steel reinforcement systems. Proper drainage and vapor barriers protect reinforcement integrity, extending service life. Properties near the Court Square area face additional challenges from urban heat island effects and de-icing salt exposure.

Seasonal Installation Factors

Cold-weather installation requires special considerations for reinforcement placement and concrete curing. Spring and fall provide optimal conditions for reinforcement installation and concrete placement. Winter projects demand heated enclosures and modified procedures affecting reinforcement selection.

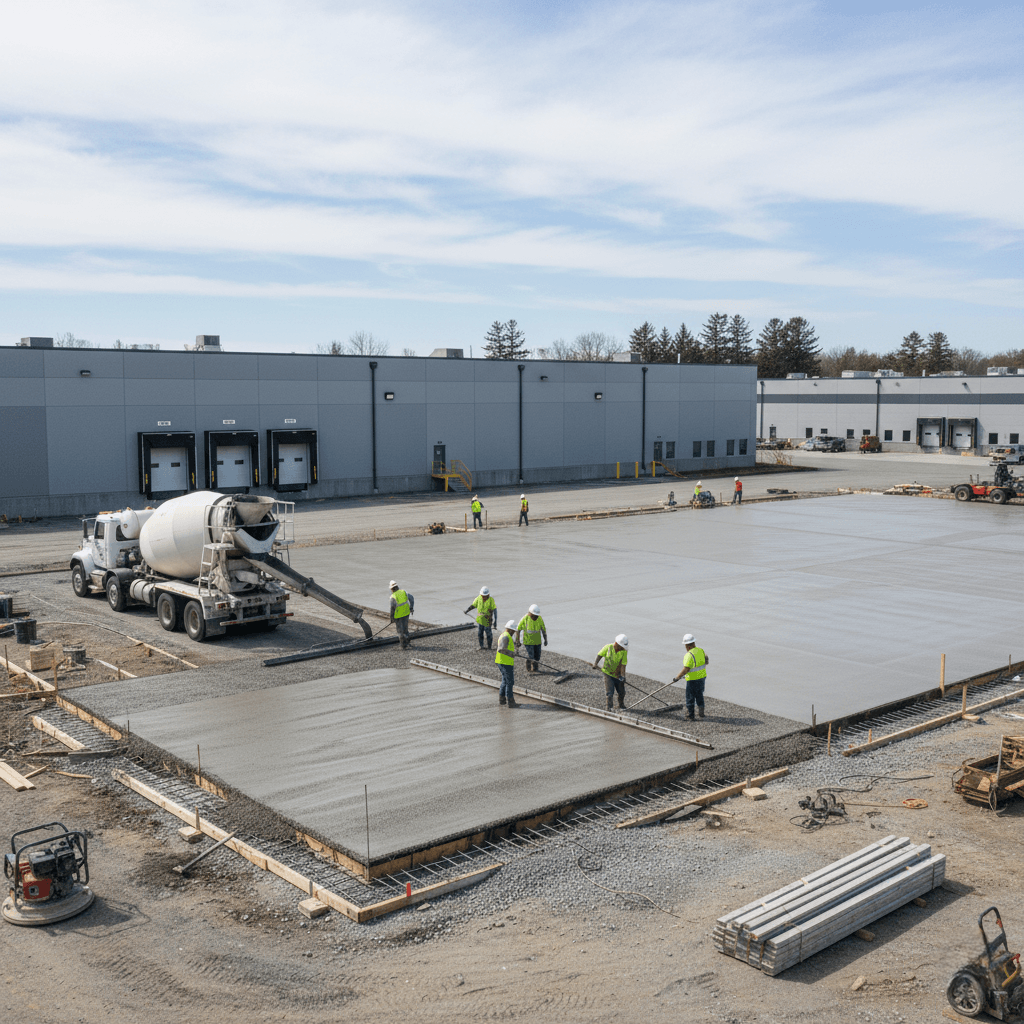

Load-Based Reinforcement Selection

Residential concrete reinforcement in Massachusetts requirements vary based on anticipated loads and structural demands. Garage slabs supporting vehicles require enhanced reinforcement compared to basement floors or patios. Heavy equipment storage areas need upgraded reinforcement systems to prevent cracking and settlement.

Foundation slabs require reinforcement addressing soil pressure and thermal movement. Properties in the Sixteen Acres area with expansive soils benefit from enhanced reinforcement, preventing differential settlement cracking. Professional structural analysis determines appropriate reinforcement for specific loading conditions.

Traffic and Load Classifications

Light residential traffic allows wire mesh or fiber reinforcement, while heavy vehicle access requires rebar systems. Commercial vehicle access mandates upgraded reinforcement specifications and increased slab thickness. Load calculations determine minimum reinforcement requirements, ensuring adequate safety factors.

Cost-Benefit Analysis

Reinforcement costs vary significantly between steel and synthetic options, affecting project budgets. Initial material costs must be balanced against long-term performance and maintenance requirements. Labor installation costs often favor mesh or fiber systems over individual rebar placement.

Long-term value considerations include service life, maintenance requirements, and potential repair costs. Properly reinforced concrete strength enhancement provides decades of reliable performance. Properties throughout Springfield benefit from reinforcement investments, preventing costly future repairs.

Budget Planning Considerations

Premium reinforcement systems justify higher costs through extended service life and reduced maintenance. Basic reinforcement provides adequate performance for standard residential applications. Professional consultation helps balance performance requirements with budget constraints.

Installation Best Practices

Professional installation ensures reinforcement effectiveness regardless of the system selected. Proper concrete cover protects steel reinforcement from corrosion while maintaining structural capacity. Consolidation techniques prevent voids around reinforcement, ensuring optimal bonding and performance.

Quality control measures verify reinforcement placement meeting design specifications. Inspection protocols identify potential issues before concrete placement, preventing costly corrections. Experienced contractors understand local requirements, ensuring code compliance and optimal performance.

Professional vs. DIY Considerations

Complex reinforcement systems require professional installation, ensuring proper placement and performance. Simple fiber reinforcement may suit experienced DIY installers with appropriate guidance. Professional installation provides warranty coverage and code compliance assurance.

We specialize in comprehensive slab construction methods throughout Springfield, providing expert guidance on optimal reinforcement selection based on specific project requirements and local conditions. Springfield Concrete Masters ensures proper reinforcement installation, maximizing concrete slab performance and longevity in Massachusetts’ demanding climate while meeting all applicable building codes and standards.