Concrete Paths & Walkways: Springfield Installation Guide

Concrete Walkway Springfield

Springfield homeowners seeking durable, attractive walkways benefit from understanding proper concrete walkway installation techniques suited to Massachusetts’ challenging climate conditions. Professional installation ensures long-lasting performance through New England’s freeze-thaw cycles while creating safe, functional pathways, enhancing property value and curb appeal. Proper planning addresses soil conditions, drainage requirements, and local building codes, ensuring compliant installations. Quality concrete walkway construction involves multiple phases from site preparation through final finishing, each critical for optimal results. Springfield’s expansive soils and variable weather patterns demand specific installation methods, preventing premature deterioration and costly repairs. Understanding these requirements helps homeowners make informed decisions about materials, contractors, and timing for successful walkway projects.

Planning and Design Considerations

Successful concrete walkway installation in Springfield projects begins with comprehensive planning addressing functionality, aesthetics, and local requirements. Standard residential walkways measure 3-4 feet wide, providing comfortable pedestrian access while accommodating wheelchairs and maintenance equipment. Path layout should follow natural traffic patterns while avoiding utility lines and tree roots.

Springfield’s building codes may require permits for walkways connecting to public sidewalks or affecting drainage patterns. Properties near Springfield College often face additional requirements due to pedestrian traffic considerations. Design elements include curves, borders, and surface textures that enhance visual appeal while maintaining functionality.

Site Assessment and Utility Location

Professional site evaluation identifies soil conditions, drainage patterns, and potential obstacles affecting installation. Underground utilities must be located and marked before excavation begins, preventing costly damage and service interruptions. Proper planning accommodates existing landscape features while ensuring adequate drainage away from structures.

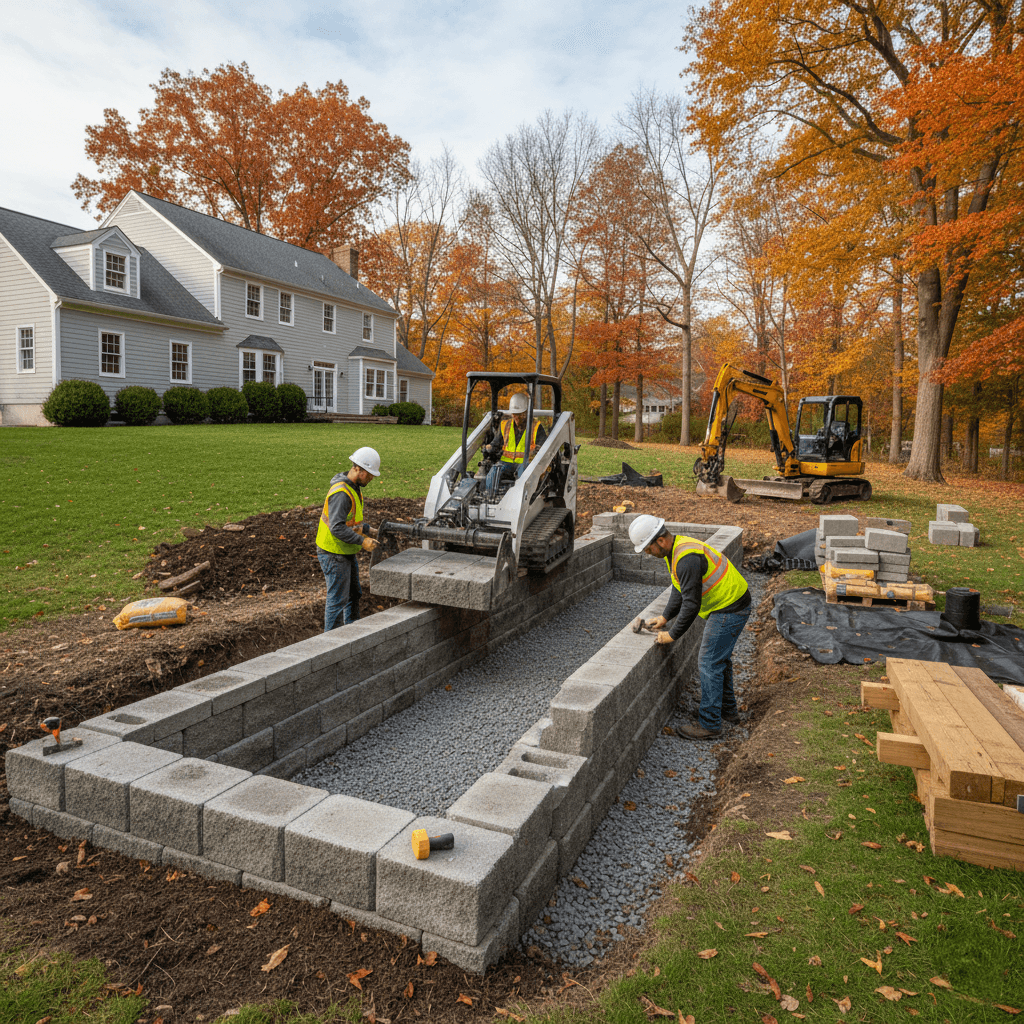

Excavation and Site Preparation

Proper excavation provides a stable foundation, preventing future settling and cracking issues. Standard excavation depth measures 6-8 inches, allowing for 4-inch concrete thickness plus base material. Springfield’s clay soils require careful handling, preventing disturbance of stable subgrade during wet conditions.

Subgrade preparation includes removing organic material, roots, and debris that could cause settling. Compaction using plate compactors ensures uniform support, preventing differential settlement. Properties in the Forest Park area may encounter challenging soil conditions requiring additional stabilization measures.

Base Material Installation

Granular base material provides drainage and frost protection essential in Massachusetts’ climate. Standard base consists of 2-4 inches of compacted gravel or crushed stone properly graded for drainage. Base material prevents frost heaving while providing a stable platform for concrete placement.

Forming and Reinforcement

Professional forming systems create precise walkway dimensions while containing concrete during placement. Forms typically use 2×4 lumber staked securely, preventing movement during the concrete pour. Proper forming includes provisions for expansion joints every 4-6 feet, preventing random cracking.

Reinforcement options include welded wire mesh or fiber reinforcement, depending on anticipated loads and soil conditions. Residential walkway construction typically uses 6×6-W2.9 wire mesh positioned mid-depth within the concrete slab. Properties near the Memorial Bridge area may require enhanced reinforcement due to traffic considerations.

Expansion Joint Planning

Expansion joints accommodate thermal movement, preventing random cracking during temperature changes. Joint spacing depends on concrete thickness, with 4-inch slabs requiring joints every 8-10 feet maximum. Proper joint installation includes full-depth saw cuts or formed joints filled with appropriate sealers.

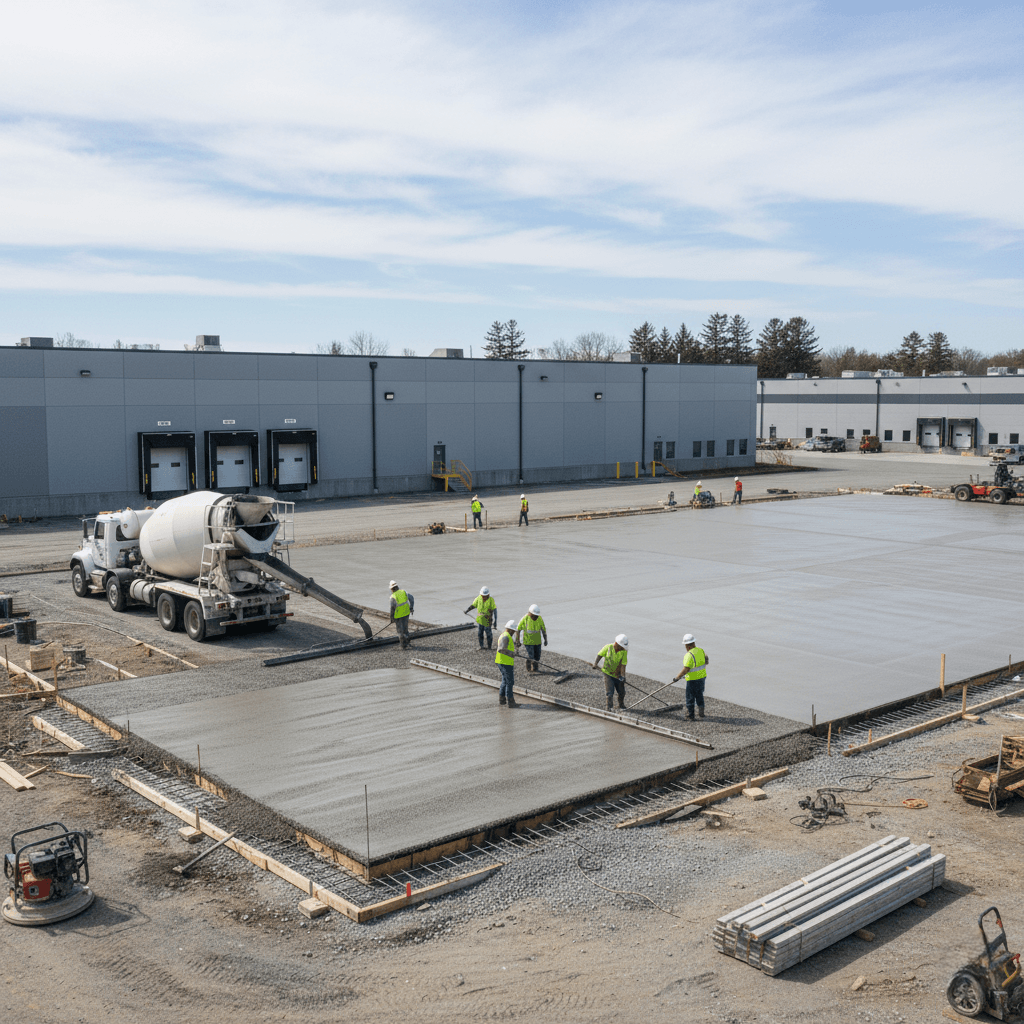

Concrete Mixing and Specifications

Massachusetts’ climate demands specific, concrete specifications ensuring durability through freeze-thaw cycles. Standard walkway concrete includes 4000 PSI minimum compressive strength with 5-7% air entrainment for frost protection. Proper mix design balances workability with long-term performance requirements.

Ready-mix concrete provides consistent quality and proper batching, ensuring optimal results. Concrete path design considerations include slump specifications allowing proper placement and finishing. Properties throughout Springfield benefit from commercial-grade mixes designed for New England climate conditions.

Quality Control Measures

Professional contractors verify concrete specifications before placement, ensuring compliance with design requirements. Temperature monitoring prevents placement during extreme conditions affecting concrete quality. Proper documentation provides warranty coverage and future reference information.

Placement and Finishing Techniques

Concrete placement requires coordinated effort, ensuring uniform thickness and proper consolidation. Placement begins at one end, working systematically toward completion, preventing cold joints. Proper screeding levels the concrete while removing excess material, creating a uniform surface.

Finishing operations include floating, edging, and texturing, creating desired surface characteristics. Walkway finishing techniques in Springfield typically include a broom finish, providing slip resistance during wet conditions. Properties in the Court Square area may require decorative finishes matching architectural themes.

Surface Texture Options

Broom finishes provide excellent traction while remaining easy to clean and maintain. Stamped concrete offers decorative options mimicking natural materials at a moderate cost increase. Exposed aggregate surfaces provide attractive, durable finishes suitable for high-traffic applications.

Curing and Protection

Proper curing develops full concrete strength while preventing surface defects and premature deterioration. Massachusetts walkway planning guide recommendations include a seven-day minimum curing period with adequate moisture retention. Curing methods include water spraying, wet burlap covering, or liquid membrane compounds.

Weather protection becomes critical during temperature extremes, preventing freeze damage or rapid moisture loss. Winter installations require heated enclosures, while summer pours need shade and frequent water application. Professional contractors understand seasonal requirements, ensuring optimal concrete development.

Timeline and Traffic Restrictions

The initial set allows light foot traffic after 24-48 hours, depending on weather conditions. Full strength development requires 28 days, though practical use begins much earlier. Heavy traffic should be avoided for a minimum of one week, preventing surface damage and joint problems.

Drainage and Water Management

Proper drainage prevents water accumulation, causing freeze damage and surface deterioration. Walkway surfaces require a minimum of 1/4 inch per foot slope, directing water away from buildings and toward appropriate outlets. Springfield’s drainage requirements consider seasonal runoff and snow melt management.

Subsurface drainage may include French drains or permeable base materials, preventing water accumulation beneath slabs. Properties in the Sixteen Acres area often require enhanced drainage due to clay soil conditions. Professional installation includes long-term drainage planning, preventing future problems.

Winter Maintenance Considerations

Proper drainage reduces ice formation while chemical-resistant concrete withstands deicing materials. Walkway design should avoid areas where snow accumulation creates ongoing maintenance challenges. Strategic planning includes snow removal access and storage areas.

Quality Control and Inspection

Professional inspection ensures installation meets design specifications and local code requirements. Quality control includes verifying proper thickness, reinforcement placement, and joint installation. Experienced contractors provide documentation supporting warranty coverage and future maintenance planning.

Final inspection confirms proper drainage, surface texture, and overall workmanship meeting project specifications. Massachusetts concrete standards require specific testing and documentation for commercial installations. Residential projects benefit from similar quality assurance measures, ensuring long-term performance.

Warranty and Maintenance Planning

Professional installations include warranty coverage protecting homeowner investments against defects and premature failure. Maintenance planning addresses sealing requirements, joint maintenance, and cleaning procedures. Proper care extends the walkway service life significantly beyond minimum expectations.

We provide comprehensive concrete walkway installation throughout Springfield, delivering professional construction services that meet local requirements while ensuring long-term durability and performance. Springfield Concrete Masters specializes in quality residential walkway construction designed to withstand Massachusetts’ challenging climate conditions while enhancing property value and safety through expert installation techniques and premium materials.