Springfield Decorative Concrete Overlays for Old Slabs

Decorative Concrete Springfield

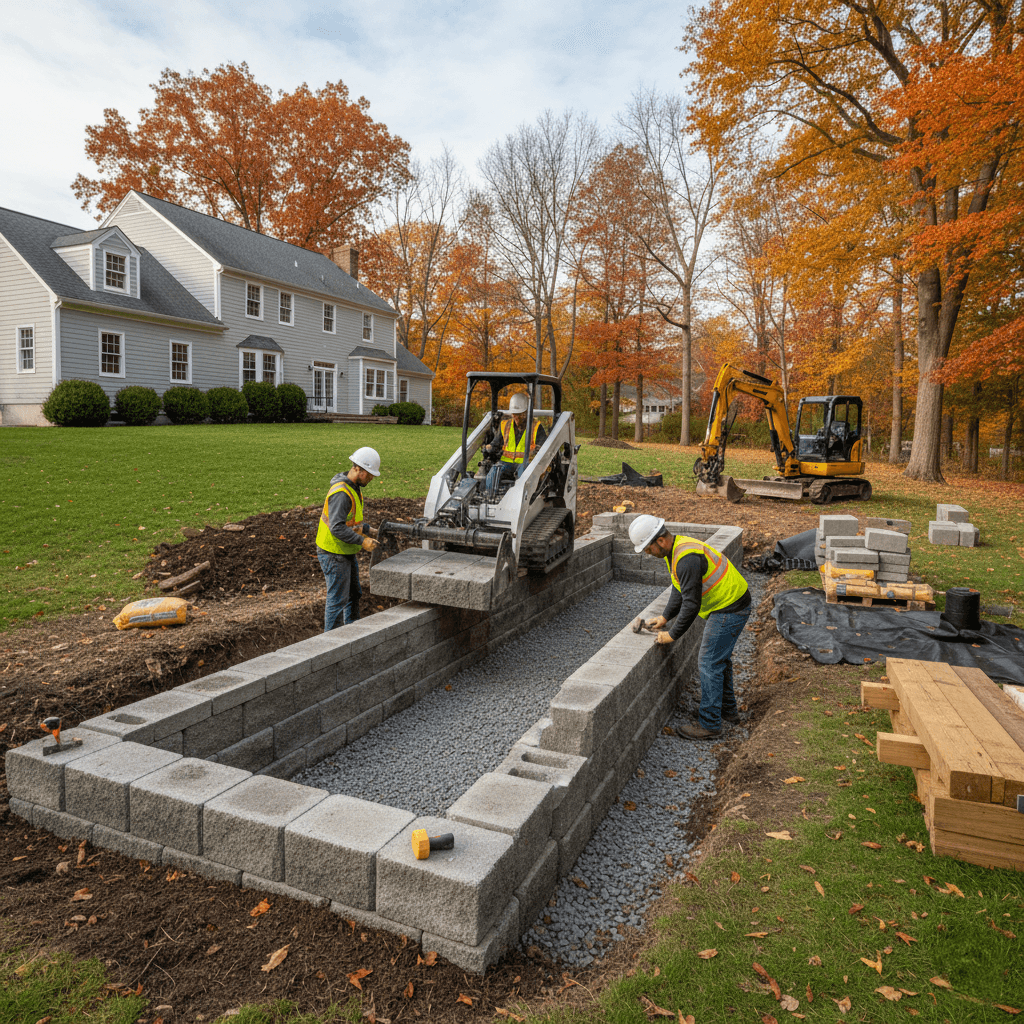

Springfield homeowners with aging concrete surfaces discover cost-effective solutions through professional overlay installations that transform tired patios, driveways, and walkways. Decorative concrete resurfacing provides dramatic visual improvements while addressing minor damage and surface imperfections common in Massachusetts properties. Expert contractors understand local climate challenges and soil conditions that affect overlay performance and longevity. Modern polymer-modified systems deliver superior adhesion and durability compared to traditional concrete repair methods. Investment in quality overlays extends surface life while dramatically enhancing curb appeal and property values throughout the Pioneer Valley region.

Understanding Decorative Concrete Overlays

Overlay systems consist of polymer-modified cement mixtures applied over existing concrete slabs to create new decorative surfaces. Thickness ranges from feather-edge applications at 1/16 inch to substantial overlays reaching 2 inches, depending on design requirements and existing surface conditions. Advanced bonding agents ensure permanent adhesion to properly prepared substrates without delamination issues.

Modern overlay materials resist freeze-thaw damage, essential for New England applications where temperature cycling threatens surface integrity. Fiber reinforcement prevents cracking while allowing natural expansion and contraction movements. Quality installations provide 15-20 year service life with proper maintenance and periodic sealing applications.

Overlay Types and Applications

Stamped overlays replicate natural stone, brick, and tile appearances through texturing techniques applied before the final set. Stained overlays incorporate integral or topical coloring that penetrates surface layers for permanent color integration. Micro-toppings provide smooth, seamless surfaces ideal for interior applications and contemporary outdoor designs.

Self-leveling overlays correct surface irregularities while creating perfectly flat installations suitable for furniture placement and entertaining areas. Spray-applied systems cover large areas efficiently while maintaining consistent thickness and appearance. Custom designs combine multiple techniques to achieve unique aesthetic results tailored to individual preferences.

Springfield Market Costs

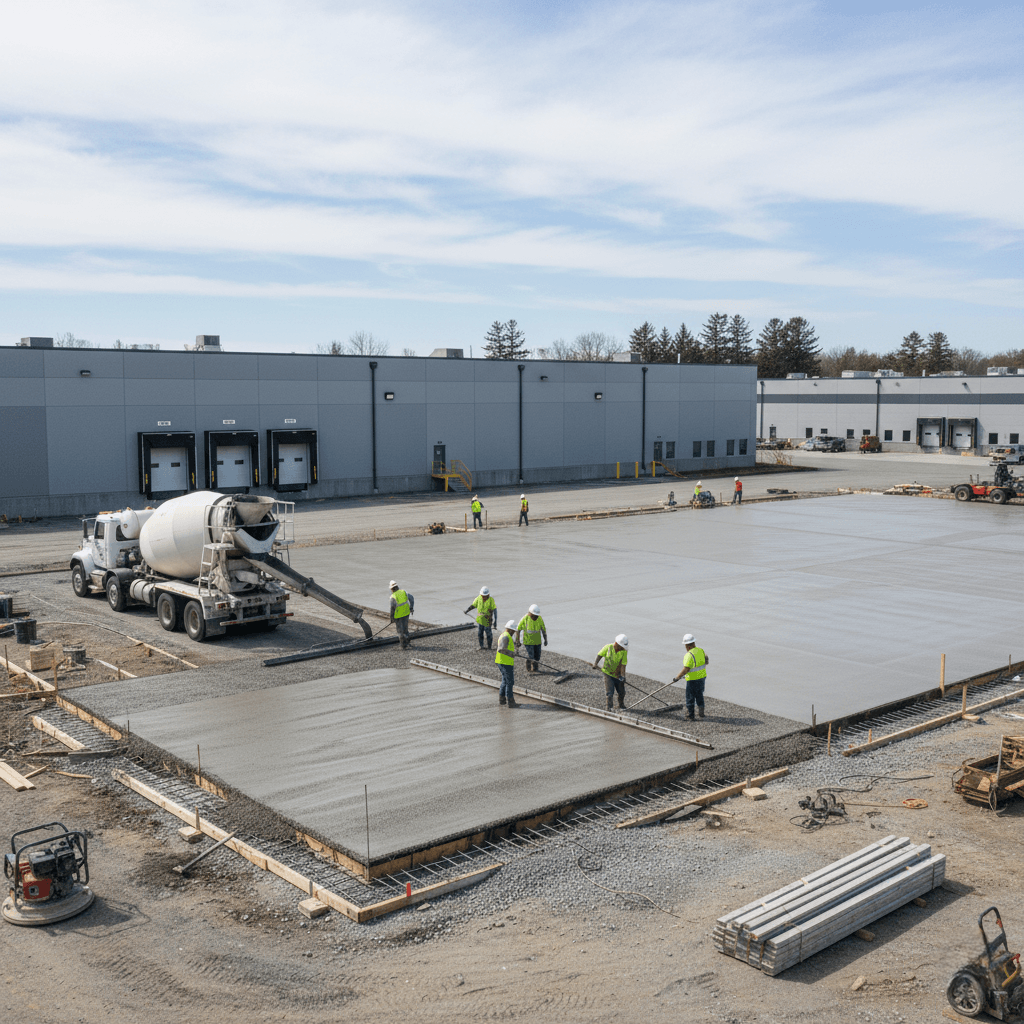

Massachusetts decorative concrete overlay pricing ranges from $6 to $10 per square foot for standard applications with basic color integration. Complex multi-color designs with intricate patterns reach $20-25 per square foot, depending on labor intensity and material requirements. Site preparation costs add $1-3 per square foot when crack repair and surface grinding become necessary.

Project size significantly influences unit pricing, with larger installations benefiting from equipment mobilization efficiencies. Residential patios typically cost $2,000-5,000 for a complete overlay installation, including preparation and sealing. Driveway resurfacing projects range from $3,000 to $8,000 based on size and design complexity specifications.

Cost Comparison Benefits

Overlay installation costs substantially less than complete concrete replacement while delivering similar aesthetic results. Demolition and disposal expenses alone often exceed total overlay project costs for equivalent areas. Time savings become significant with overlay completion in 2-3 days versus weeks required for removal and replacement projects.

Property value increases from decorative overlays typically return 70-80% of investment costs when properties change ownership. Enhanced curb appeal attracts potential buyers while demonstrating property maintenance commitment. Long-term cost benefits include reduced maintenance requirements compared to aged concrete surfaces.

Surface Preparation Requirements

Successful overlay installation demands thorough surface preparation, including cleaning, crack repair, and mechanical abrading for optimal adhesion. Pressure washing removes dirt, grease, and surface contaminants that prevent proper bonding. Chemical etching opens concrete pores to enhance overlay penetration and mechanical lock.

Crack repair utilizes flexible sealants that accommodate minor movement without overlay failure. Grinding high spots and filling low areas creates uniform substrate conditions essential for consistent overlay thickness. Moisture testing ensures concrete moisture levels meet manufacturer specifications before overlay application.

Springfield Climate Considerations

New England freeze-thaw cycles require specialized overlay formulations with enhanced flexibility and air entrainment. Installation timing avoids extreme temperatures that compromise curing and final strength development. Spring and fall seasons provide optimal conditions for proper overlay bonding and curing processes.

Drainage assessment prevents water accumulation that could undermine overlay adhesion over time. Proper slope design directs runoff away from structures while maintaining an attractive appearance. Winter protection includes avoiding deicing chemicals that can damage overlay surfaces and compromise longevity.

Design Options and Aesthetics

Color possibilities include earth tones that complement Springfield’s natural landscape and architectural styles found throughout neighborhoods near the Springfield Armory National Historic Site and the Connecticut River corridor. Texture options range from smooth contemporary finishes to rustic stone appearances suitable for historic district properties.

Pattern integration creates visual interest through geometric designs, borders, and accent elements that define outdoor living spaces. Seamless transitions between different surface areas maintain design continuity while addressing varying functional requirements. Professional design consultation ensures optimal results that enhance existing landscape elements.

Regional Design Preferences

Springfield homeowners favor designs that complement New England architectural traditions while incorporating modern functionality requirements. Natural stone appearances work well with colonial and Victorian home styles common throughout the Pioneer Valley region. Contemporary geometric patterns suit modern developments while respecting neighborhood character.

Color selection considers seasonal changes and year-round appearance requirements typical of Massachusetts climate conditions. UV-resistant pigments maintain vibrancy throughout intense summer sun exposure. Slip-resistant textures provide safety benefits during wet conditions common in humid New England summers and icy winter months.

Installation Process Overview

Professional installation begins with a comprehensive substrate evaluation to identify potential issues before overlay application. Surface preparation proceeds systematically to ensure optimal conditions for overlay bonding and long-term performance. Environmental controls maintain proper temperature and humidity during critical curing periods.

Application techniques vary by overlay type, with spray systems covering large areas efficiently while hand-troweled applications provide precise control for detailed work. Quality control measures ensure consistent thickness, color, and texture throughout the entire installation area. Timing coordination prevents delays that could compromise overlay quality.

Curing and Protection

Proper curing requires controlled conditions that optimize overlay strength development and surface durability. Moisture retention techniques prevent rapid drying that causes surface defects and reduced performance. Temperature monitoring ensures optimal curing conditions regardless of seasonal variations.

Initial protection includes traffic restrictions and weather shielding during critical early curing periods. Sealer application timing follows manufacturer recommendations for optimal penetration and protection. Final inspection verifies installation quality and addresses any minor adjustments before project completion.

Maintenance and Longevity

Routine maintenance includes regular cleaning with mild detergents and soft brushing to remove surface debris and stains. Annual inspection identifies potential issues before they develop into costly repair requirements. Professional maintenance services provide comprehensive care, including cleaning, minor repairs, and sealer reapplication.

Sealer reapplication every 3-5 years maintains surface protection and color vibrancy throughout Massachusetts’ seasonal extremes. Quality sealers enhance stain resistance while providing slip-resistant surfaces for safety considerations. Proper maintenance extends overlay life significantly beyond untreated installations.

Problem Prevention

Common issues include surface scaling from freeze-thaw damage, which is preventable through proper installation techniques and quality materials. Stain prevention requires prompt cleanup of spills and regular sealer maintenance. Traffic damage is minimized through appropriate overlay thickness selection and reinforcement specifications.

Professional troubleshooting addresses minor problems before they become major repairs requiring extensive work. Early intervention maintains appearance and performance while controlling long-term costs. Regular professional evaluation ensures optimal overlay condition throughout the expected service life.

Springfield Concrete Masters specializes in transforming aging concrete surfaces through professional decorative concrete overlay installations. Our experienced team understands local conditions and delivers superior results that enhance property values while providing lasting beauty and functionality for residential and commercial applications throughout the Springfield area.