Springfield Commercial Concrete: Flatwork Installation Tips

Commercial Concrete Springfield

Springfield businesses require durable concrete solutions that withstand heavy commercial traffic while maintaining a professional appearance throughout demanding operational cycles. Professional commercial concrete installation demands specialized techniques and equipment designed for large-scale industrial applications. Massachusetts climate conditions present unique challenges requiring expert knowledge of freeze-thaw resistant materials and installation procedures. Quality flatwork contractors understand local soil conditions and building codes essential for successful long-term performance. Investment in superior concrete flatwork installation delivers decades of reliable service while enhancing property values in competitive commercial markets.

Commercial Concrete Fundamentals

Industrial-grade concrete specifications exceed residential requirements through enhanced strength ratings and specialized additives designed for heavy-duty applications. PSI ratings typically range from 4000-6000 for commercial flatwork, depending on intended use and traffic expectations. Fiber reinforcement prevents cracking while steel reinforcement provides structural integrity under heavy equipment loads.

Proper concrete mix design incorporates air entrainment, essential for Massachusetts freeze-thaw resistance during harsh New England winters. Quality aggregate selection ensures consistent performance while reducing maintenance requirements over extended service periods. Professional installation techniques maximize material performance through precise placement and finishing procedures.

Springfield Market Applications

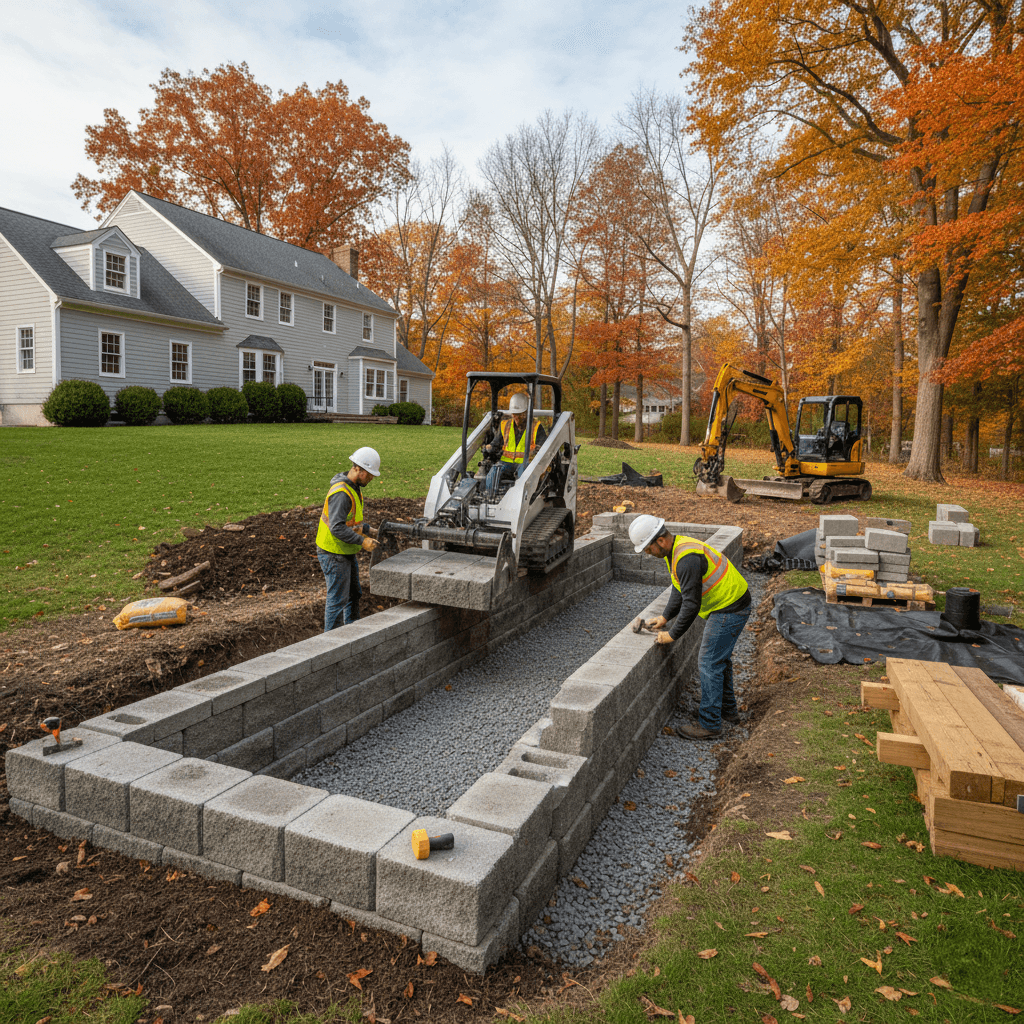

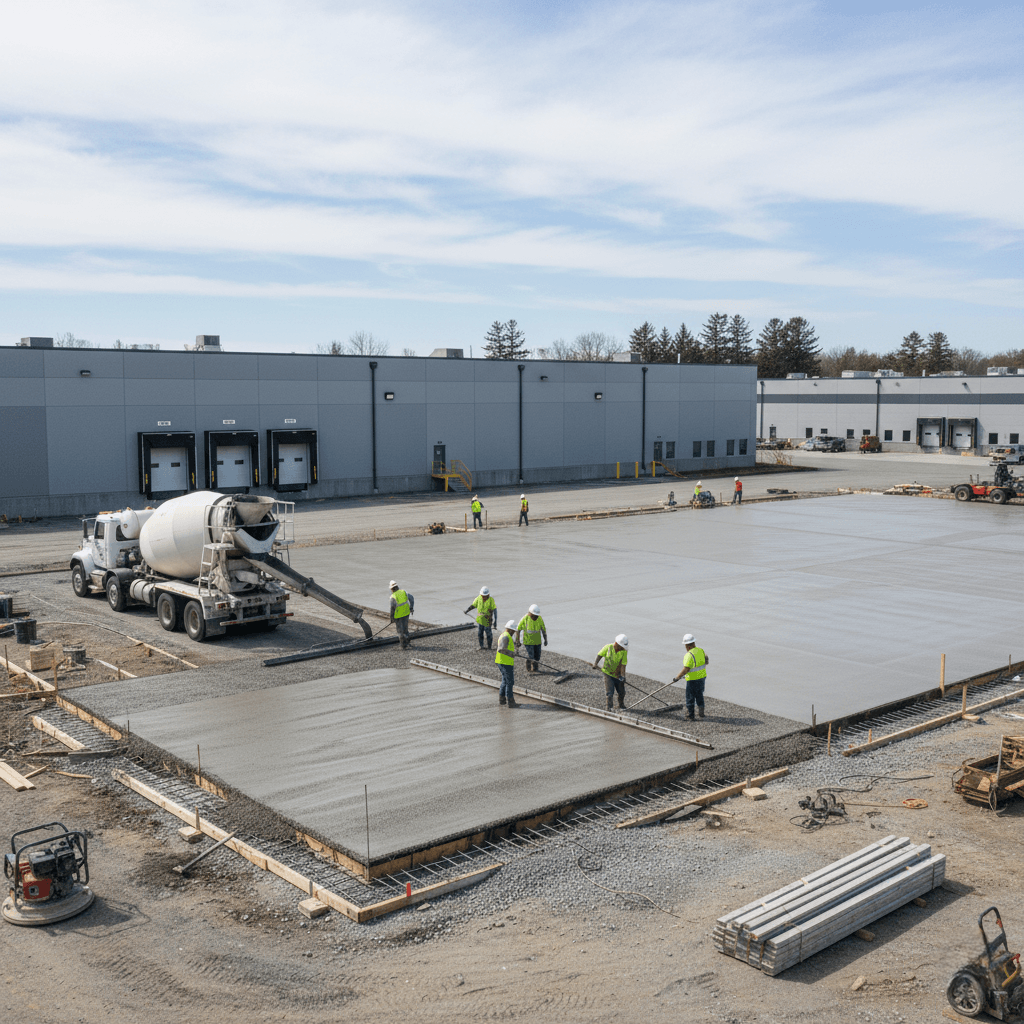

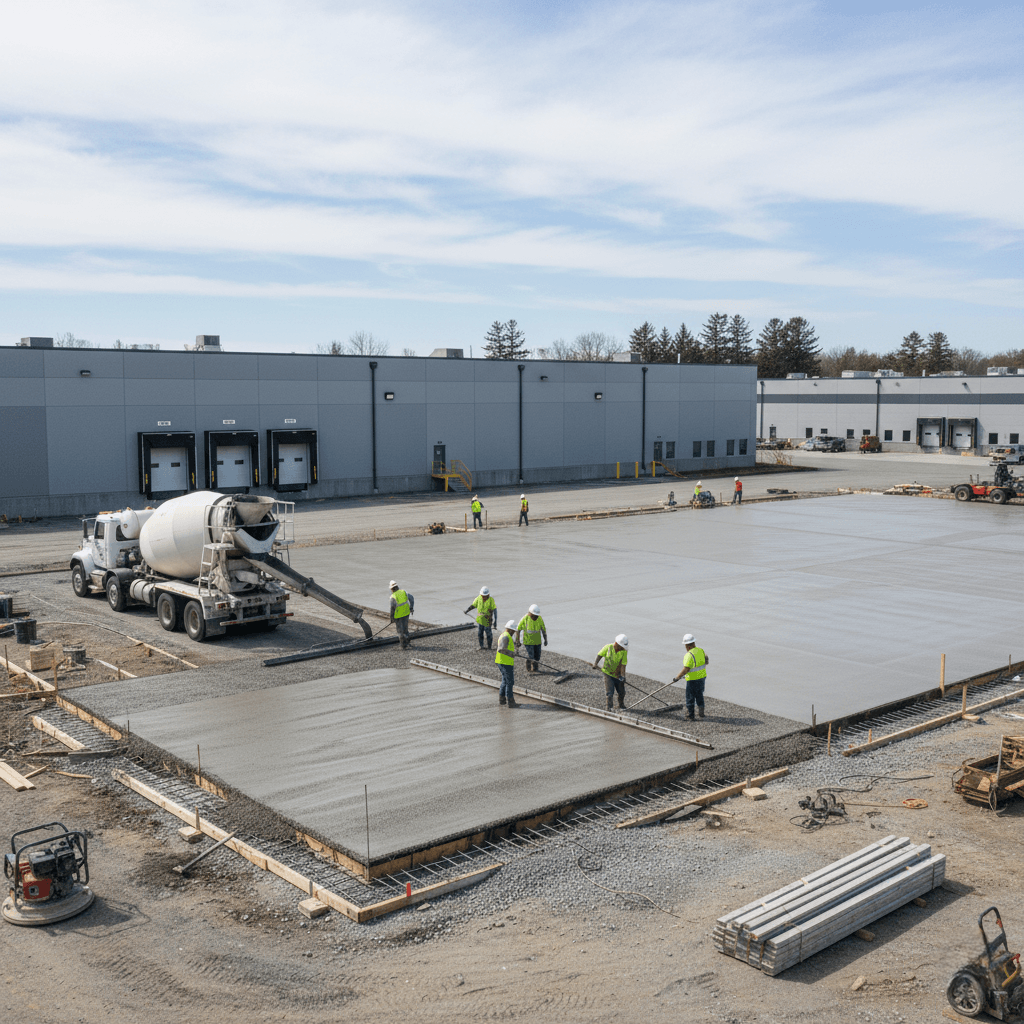

Warehouse facilities near major transportation corridors require specialized concrete flooring capable of supporting heavy forklift traffic and storage equipment. Distribution centers benefit from superflat concrete specifications that enable efficient automated systems operation. Manufacturing plants demand chemical-resistant surfaces that maintain structural integrity under industrial processes.

Retail spaces utilize decorative concrete techniques that combine durability with aesthetic appeal, suitable for customer environments. Office complexes require smooth, level surfaces that support furniture placement while maintaining a professional appearance. Medical facilities need seamless installations that facilitate cleaning and sanitation requirements.

Flatwork Installation Techniques

Professional concrete flatwork installation begins with comprehensive site preparation, including soil testing and grade verification to ensure optimal foundation conditions. Laser-guided grading equipment achieves precise elevations essential for proper drainage and equipment operation. Vapor barriers prevent moisture migration that could compromise adhesion and surface integrity.

Strategic joint placement accommodates thermal expansion while maintaining structural continuity across large installation areas. Control joints utilize saw-cutting techniques that direct cracking along predetermined lines rather than random locations. Isolation joints separate concrete sections to prevent differential movement damage.

Advanced Placement Methods

Concrete pumping systems enable efficient placement in areas inaccessible to traditional delivery trucks while maintaining consistent mix quality. Boom pumps reach elevated locations and confined spaces common in industrial construction projects. Line pumps provide precise control for detailed placement requirements around equipment and infrastructure.

Power screeding equipment ensures uniform surface levels across large areas while consolidating concrete for optimal density. Laser-guided screeds maintain precise elevations essential for equipment installation and operational requirements. Quality control measures verify thickness and grade specifications throughout the installation process.

Surface Finishing Standards

Commercial concrete finishing requires specialized techniques that balance functionality with durability under demanding operational conditions. Float finishing creates dense surfaces resistant to wear while maintaining appropriate texture for safety requirements. Trowel finishing produces smooth surfaces suitable for equipment installation and material handling operations.

Superflat specifications become essential for automated warehouse systems requiring precise floor tolerances for optimal equipment performance. FL numbers specify floor levelness while FF numbers indicate floor flatness according to industry standards. Professional finishing crews utilize specialized equipment to achieve demanding tolerance requirements.

Industrial Coating Systems

Epoxy coating applications provide chemical resistance and enhanced durability for manufacturing and processing facilities. Urethane systems offer superior abrasion resistance for high-traffic areas subject to heavy equipment operation. Polyaspartic coatings deliver rapid curing times that minimize downtime during installation projects.

Anti-slip additives improve safety in areas exposed to moisture or chemical spills common in industrial environments. Color coding systems facilitate traffic flow and safety zone identification throughout large facilities. Professional coating application ensures optimal adhesion and long-term performance under demanding conditions.

Springfield Cost Considerations

Massachusetts commercial concrete costs typically range from $10 to $15 per square foot for standard industrial flatwork, including materials and professional installation. Specialized applications requiring enhanced specifications or decorative elements reach $20-30 per square foot, depending on complexity requirements. Site conditions significantly influence pricing through preparation and access considerations.

Project scale affects unit pricing, with large installations benefiting from equipment mobilization efficiencies and material purchasing advantages. Warehouse projects exceeding 50,000 square feet often achieve economies of scale, reducing per-square-foot costs substantially. Timing coordination with other construction activities optimizes efficiency while controlling overall project expenses.

Value Engineering Opportunities

Strategic phasing allows business operations to continue during installation while spreading costs across multiple budget periods. Alternative reinforcement methods balance performance requirements with cost considerations for specific application needs. Material selection optimization achieves required performance standards while controlling unnecessary premium specifications.

Long-term cost analysis includes maintenance requirements and lifecycle expenses that favor quality installations over lower initial cost alternatives. Energy efficiency benefits through thermal mass properties reduce operational costs in climate-controlled facilities. Professional consultation identifies cost-effective solutions that meet performance requirements within budget constraints.

Quality Control Protocols

Comprehensive testing programs ensure concrete meets specified strength and durability requirements through systematic sampling and laboratory analysis. Slump testing verifies proper consistency during placement, while air content measurements confirm adequate freeze-thaw resistance. Compressive strength testing at prescribed intervals validates the achievement of design specifications.

Surface quality inspection utilizes precision instruments to verify flatness and levelness tolerances essential for equipment operation. Moisture testing prevents premature coating application that could compromise adhesion and long-term performance. Professional documentation verifies for warranty coverage and quality assurance purposes.

Performance Monitoring

Regular inspection schedules identify potential issues before they develop into costly repair requirements affecting business operations. Crack monitoring systems track movement patterns that indicate structural performance or environmental influences. Professional evaluation provides recommendations for preventive maintenance that extend service life significantly.

Thermal monitoring during curing prevents temperature-related stress that could compromise final strength development. Moisture management systems prevent water accumulation that undermines surface integrity over time. Documentation systems track performance metrics that support warranty claims and future planning decisions.

Regional Compliance Requirements

Massachusetts building codes mandate specific requirements for commercial concrete installation, including strength specifications and inspection procedures. Springfield’s Department of Inspectional Services oversees compliance verification through systematic review and field inspection protocols. Professional contractors maintain current certification, ensuring adherence to evolving regulatory requirements.

Environmental regulations address stormwater management and waste disposal during construction activities, affecting project planning and execution. OSHA safety requirements mandate specific procedures for worker protection during concrete placement and finishing operations. ADA compliance ensures accessibility features meet federal requirements for public accommodation facilities.

Permit and Inspection Process

Commercial building permits require detailed plans showing concrete specifications, reinforcement details, and environmental considerations. Professional plan review ensures code compliance while identifying potential issues before construction begins. Inspection scheduling coordinates with concrete placement to ensure timely approval without delays affecting curing schedules.

Special permits may be required for projects affecting traffic patterns or requiring utility modifications near major corridors like Interstate 91 or Route 20. Professional contractors navigate regulatory requirements efficiently while maintaining project schedules. Compliance documentation supports final approvals and occupancy permits essential for business operation.

Springfield Concrete Masters brings extensive experience in commercial concrete and flatwork installation throughout the greater Springfield area. Our professional team specializes in delivering superior results for warehouses, retail facilities, and industrial projects while meeting demanding schedules and quality standards that support successful business operations.