Springfield Concrete Pouring: Vibrating, Screeding & Curing

Pouring Concrete Springfield

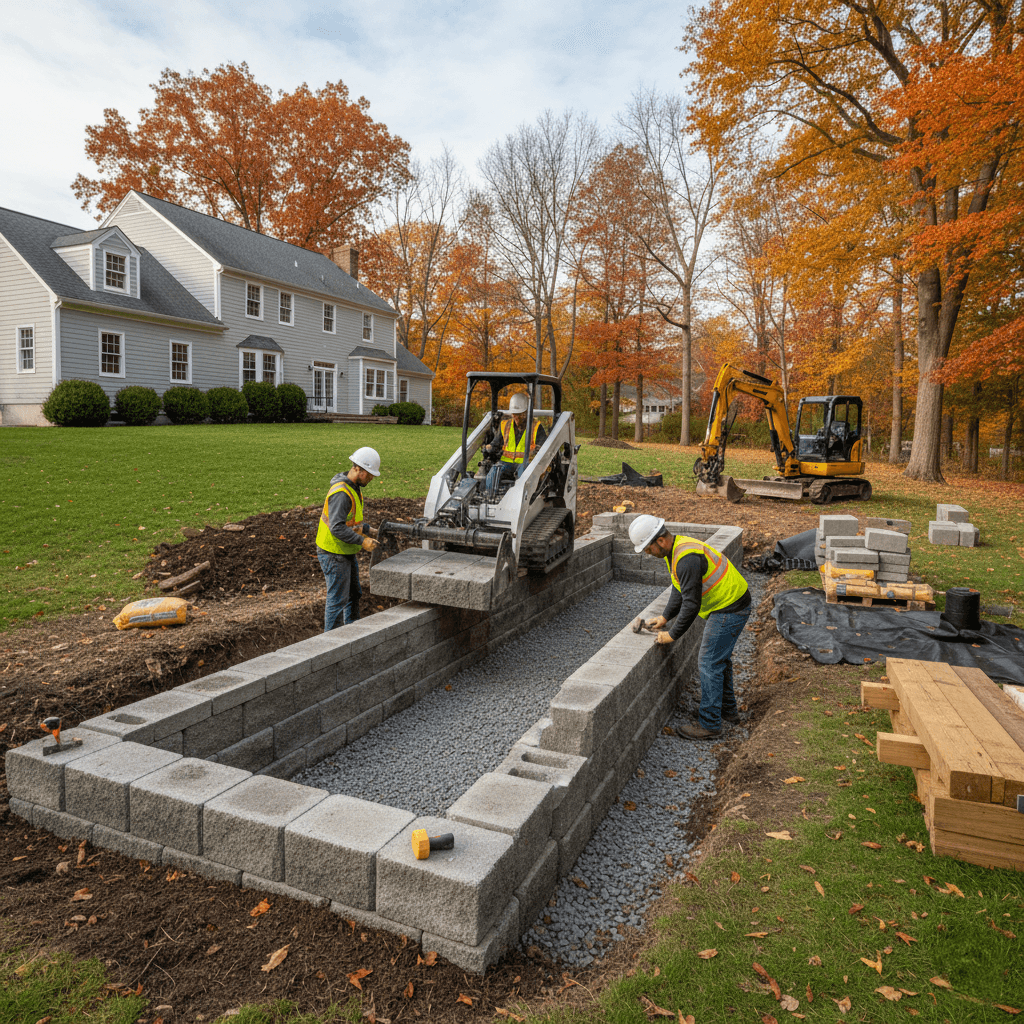

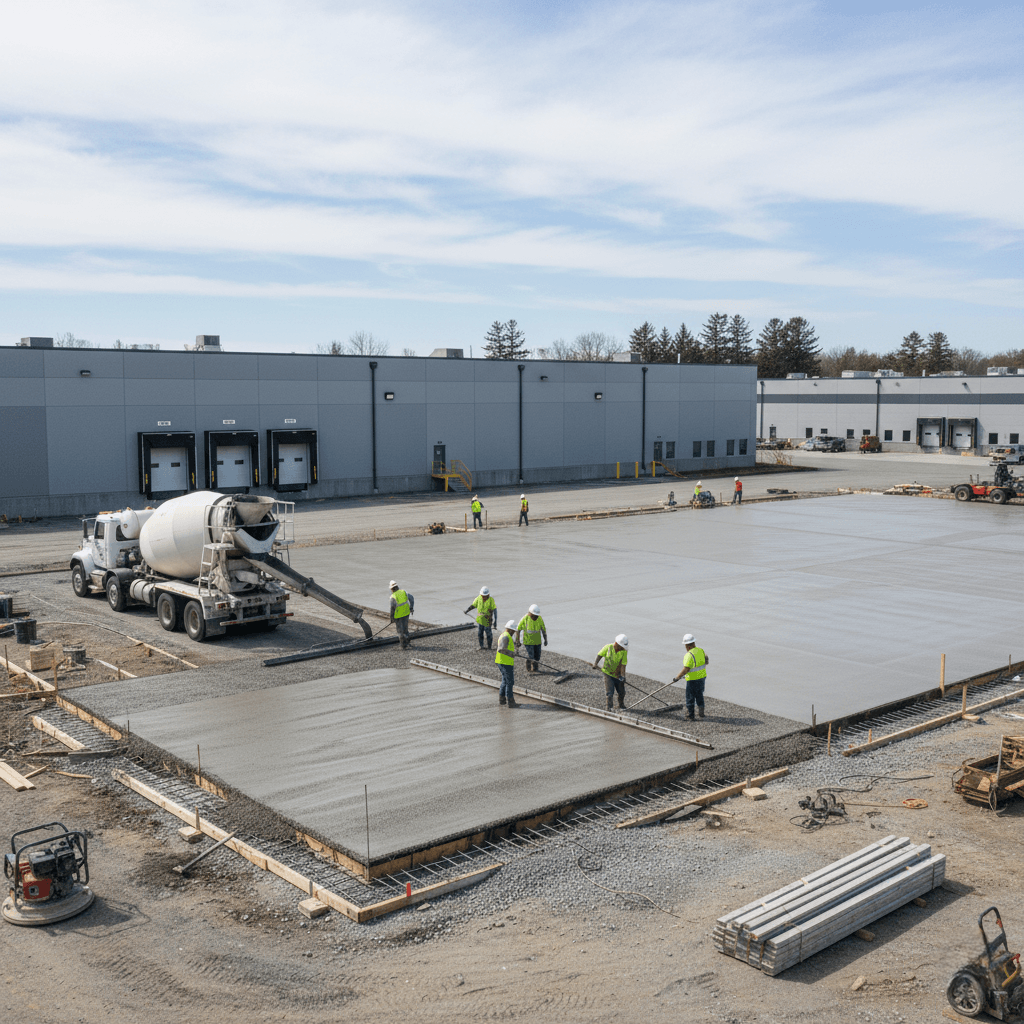

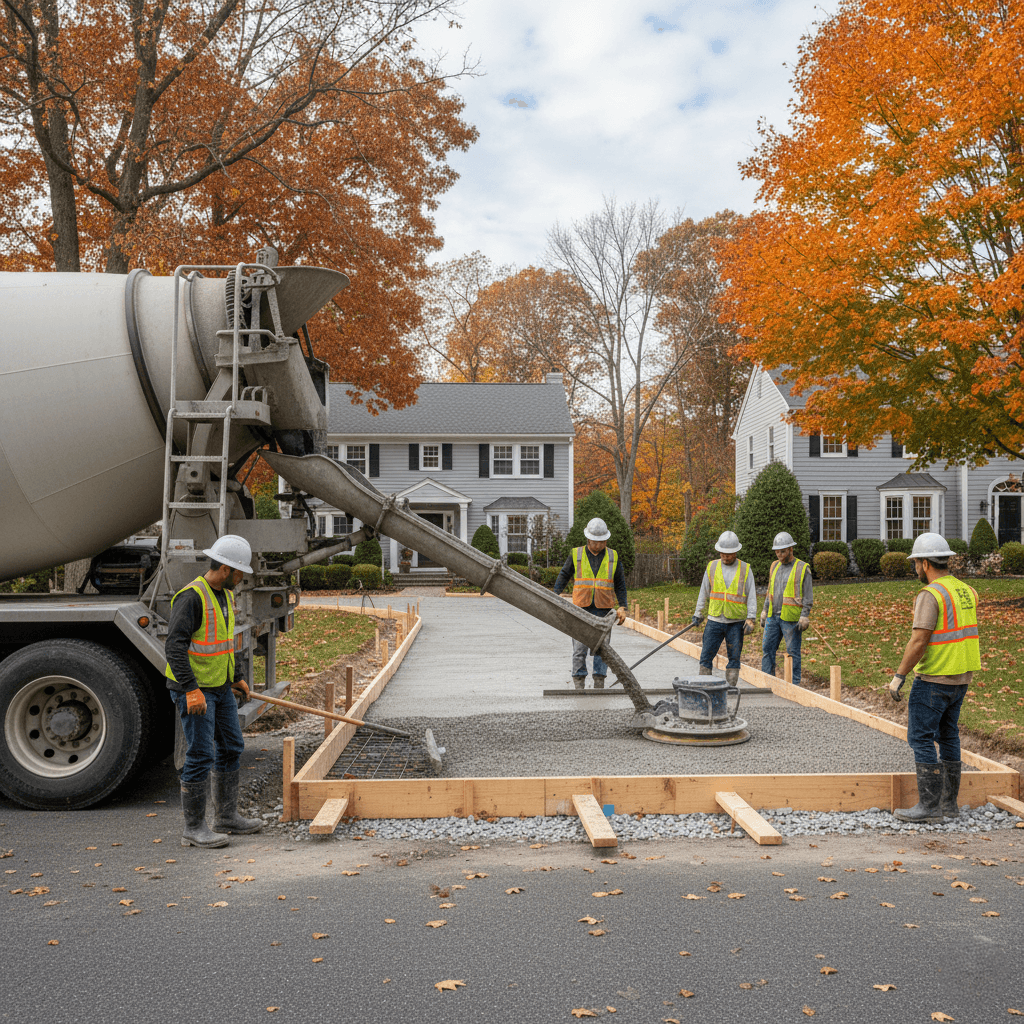

Professional concrete installation requires precise techniques and expert knowledge of local building requirements. Advanced vibrating, screeding, and curing methods ensure superior concrete placement throughout Springfield, Massachusetts projects. Experienced teams understand the unique challenges of New England climate conditions and Massachusetts building codes. Each project receives careful attention to detail, ensuring optimal strength and durability. Traditional craftsmanship combined with modern equipment achieves exceptional results for residential and commercial applications.

Essential Concrete Vibrating Techniques

Proper vibration eliminates air pockets and ensures uniform concrete consolidation throughout your project. Internal vibrators penetrate deep into the concrete mix, removing trapped air that can compromise structural integrity. Surface vibrators work effectively for slabs six inches or less in depth, creating smooth finishes ideal for driveways and patios.

Our technicians insert vibrating equipment at systematic intervals, maintaining consistent patterns across the entire pour. The process requires careful timing to prevent over-vibration, which can cause bleeding and surface defects. Temperature considerations become crucial during Springfield’s varying seasonal conditions, as concrete sets faster in summer heat and slower during winter months.

Power Vibrating Equipment

Professional-grade vibrating tools significantly enhance concrete strength and appearance. Electric and pneumatic vibrators offer reliable performance for different project scales. Handheld units provide precise control for detailed work around reinforcement bars and corners.

Vibrating screeds combine leveling and consolidation in a single operation, improving efficiency on larger installations. These specialized tools reduce labor requirements while maintaining consistent quality standards. Proper maintenance of vibrating equipment ensures optimal performance throughout the construction season.

Professional Screeding Methods

Screeding creates level surfaces and proper elevations essential for successful concrete installation. Traditional hand screeding works well for smaller residential projects, while power screeds handle larger commercial applications efficiently. The screeding process removes excess concrete while bringing the surface to the desired grade specifications.

Springfield building codes require specific elevation standards for residential foundations and commercial structures. Our team uses laser levels and grade stakes to maintain precise measurements throughout the screeding operation. Proper screed board selection depends on project width and concrete consistency.

Advanced Screeding Techniques

Magnesium and aluminum screed boards provide lightweight alternatives to traditional wooden tools. These materials resist concrete adhesion and offer improved durability across multiple projects. Vibrating screeds combine consolidation with leveling, particularly beneficial for large slabs near Forest Park residential developments.

Edge screeding requires special attention to achieve clean transitions and prevent cracking along perimeters. Control joints placed at appropriate intervals accommodate natural expansion and contraction cycles. Strategic placement prevents unsightly cracks while maintaining structural integrity.

Optimal Curing Processes

Effective curing maximizes concrete strength and longevity through controlled moisture retention and temperature management. Springfield’s climate variations require adaptive curing strategies throughout different seasons. Hot summer weather accelerates setting times, while cold conditions may require heated curing methods.

Wet curing maintains optimal moisture levels for chemical hydration processes that develop concrete strength. Curing compounds create protective barriers against rapid moisture loss, particularly important during windy conditions common near the Connecticut River. Proper curing duration varies based on concrete mix design and environmental factors.

Seasonal Curing Considerations

Winter concrete placement demands special precautions to prevent freeze damage during initial setting periods. Heated enclosures and insulating blankets protect freshly poured concrete from freezing temperatures. Spring installation projects benefit from moderate temperatures and consistent moisture conditions.

Summer curing requires protection from excessive heat and rapid moisture evaporation. Shade structures and frequent water application maintain proper hydration rates. Fall projects must account for decreasing temperatures and potential early frost conditions affecting curing schedules.

Springfield Building Code Compliance

Massachusetts building regulations mandate specific requirements for concrete installation and inspection procedures. Springfield’s Department of Inspectional Services oversees permit applications and compliance verification for residential and commercial projects. Building permits must be obtained before construction begins, ensuring adherence to safety and quality standards.

The Massachusetts State Building Code incorporates International Building Code standards with local amendments addressing regional construction challenges. Concrete specifications include minimum compressive strength requirements and proper reinforcement placement. Regular inspections verify compliance throughout the installation process.

Permit Requirements

Foundation work requires building permits from Springfield’s Code Enforcement division, located at City Hall. Permit applications must include detailed plans showing concrete specifications and reinforcement details. Professional contractors handle permit acquisition and inspection scheduling to ensure timely project completion.

Special permits may be required for projects near historic districts or environmentally sensitive areas around the Basketball Hall of Fame vicinity. Zoning compliance verification prevents costly delays and ensures legal conformity. Our team manages all regulatory requirements from application through final approval.

Quality Control and Testing

Comprehensive testing ensures concrete meets specified strength and durability requirements. Slump tests verify proper consistency and workability before placement begins. Compressive strength testing at seven and twenty-eight days confirms performance specifications.

Air content measurements ensure proper freeze-thaw resistance for Springfield’s climate conditions. Temperature monitoring during placement and curing maintains optimal conditions for strength development. Professional testing protocols provide documentation for warranty and liability purposes.

Advanced Testing Methods

Non-destructive testing methods evaluate concrete quality without damaging finished surfaces. Core sampling provides accurate strength verification for critical structural elements. Maturity monitoring systems track concrete development in real-time during curing periods.

Quality assurance programs include material certification and batch documentation for traceability. Regular calibration of testing equipment ensures accurate and reliable results. Comprehensive record-keeping supports warranty claims and future maintenance planning.

Professional testing protocols provide documentation for warranty and liability purposes while ensuring long-term structural performance. Springfield Concrete Masters brings years of experience and expertise to every concrete installation project throughout the Springfield area. We specialize in professional pouring concrete services for residential and commercial applications, delivering superior results that meet the highest industry standards.